Trenchless Pipe Relining Market

Contents |

[edit] Introduction

Trenchless pipe relining technologies are gaining traction in the global market, due to their outstanding performance and technical advantages. These techniques repair existing underground pipelines by inserting a relatively small diameter pipe or by spraying coating material into the damaged pipe to create a lining within the pipe, with very limited or no excavation.

The key features of these techniques are that the pipe relining has become faster, easier, cheaper, and cleaner. In addition, they avoid traffic jams, destruction of landscape, and other environmental impacts.

Ageing existing pipeline infrastructure, increasing deterioration rate, growing population, and urbanisation in the key countries, such as the USA, Germany, and Canada, have led to an increased focus on trenchless pipe relining techniques to reduce water loss and rehabilitate infrastructure while avoiding traffic jams and destruction of landscaping.

The USA alone has more than 9.5 billion feet of the installed pipeline of which most were laid in mid of the 20th century. Similarly, in the European Union states, around 23 billion feet of pipes are in operation from the last 100 years. In Japan, about 15% of water pipes have outlived their 40-year duration as of 2016.

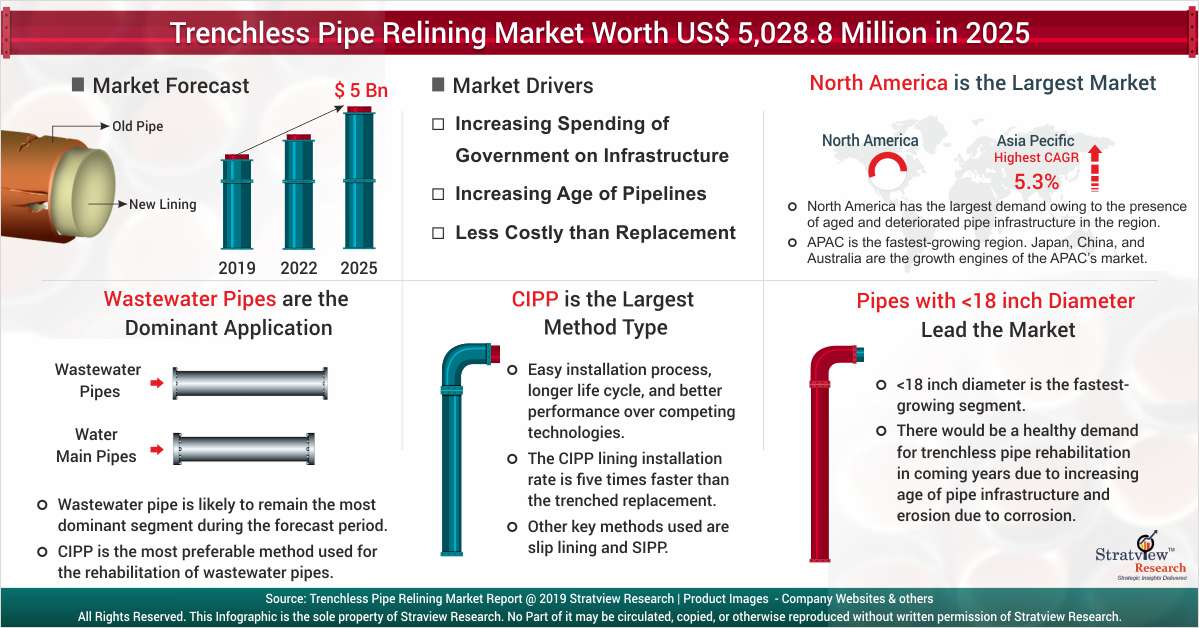

The trenchless pipe relining market is projected to grow at an impressive rate over the next five years to reach an estimated value of US$ 5.0 billion in 2025. The market is mainly driven by an ageing existing pipeline network coupled with a surge in spending of government and municipal corporations to repair and maintain existing pipes.

[edit] Market by method

Based on method, CIPP is projected to remain the dominant as well as the fastest-growing segment in the market during the forecast period. The dominance of CIPP technology is mainly due to its fast and easy installation process, longer life cycle, and better performance over competing technologies. The CIPP lining installation rate is five times faster than the trenched replacement.

[edit] Market by application

Based on the application type, wastewater pipe is likely to remain the dominant segment during the forecast period. CIPP is the preferable method used for the rehabilitation of wastewater pipes. However, watermain pipe is expected to witness the highest growth during the forecast period. The equipment and liner materials used during relining have to be compliant under the certification and standards of NSF/ANSI 61, which has norms related to the material used for the lining of water main pipelines in order to prevent contamination of injurious substances of liners with the potable drinking water.

[edit] Regional analysis

In terms of region, North America is projected to remain the largest market for trenchless pipe relining during the forecast period. The average active service life of a pipeline installed is around 50 years and most have exceeded this. Relining provides an extension of around 30-50 years to the pipe.

Asia-Pacific is expected to witness the highest growth during the forecast period. Japan, China, and Australia are the growth areas of the Asia-Pacific's trenchless pipe relining market. These economies will generate demand to decrease water loss and improve water quality.

The supply chain for this market comprises raw material and equipment suppliers, trenchless pipe relining service providers/contractors, governments, municipal corporations, and public welfare societies.

Some of the key players in the trenchless pipe relining market are Aegion Corporation, Granite Construction Inc., Inland Pipe Rehabilitation LLC (IPR), Per Aarsleff A/S, and SAK Construction, LLC. The key customers of these players include state governments and local authorities of America, Federation of Canadian Municipalities, and Private Builders.

[edit] Related articles on Designing Buildings Wiki

Featured articles and news

A case study and a warning to would-be developers

Creating four dwellings for people to come home to... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.

Futurebuild and UK Construction Week London Unite

Creating the UK’s Built Environment Super Event and over 25 other key partnerships.

Welsh and Scottish 2026 elections

Manifestos for the built environment for upcoming same May day elections.

Advancing BIM education with a competency framework

“We don’t need people who can just draw in 3D. We need people who can think in data.”